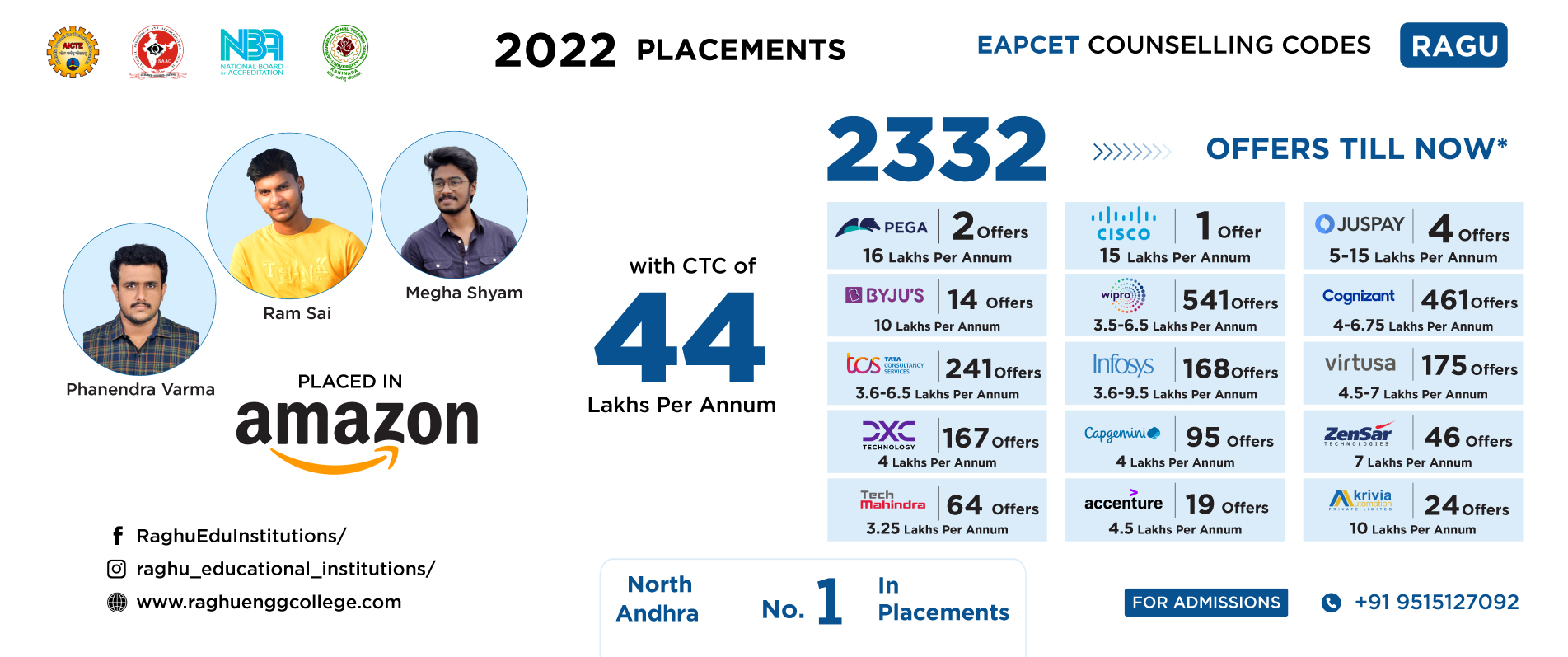

Impeccable Placements Record

Single Destination for Countless opportunities.

Pavan Chaitanya

Senior System Architect

Bharghavi

System Analyst

Megha Shyam

SD Engineer

Chandralekha

Software Engineer

Radha Priya

Assistant System Engineer

Udhay Vihar

Digital Specialist Engineer

2332 placements in 48 global corporates for 2022 batch

Join us to tap the most lucrative job opportunities right at the launch because of the focused training education underpinning the academic foundation. We lead in mining for opportunities with the highest packages!

Why study at Raghu Engineering College?

31 Years of committed excellence in education

JNTUK Recognized Research Centre

Ranked No.1 in North Andhra for Placements

Accredited by NAAC with ‘A+’ Grade

12b & 2f Autonomous

Re-Accredited by NBA

50 Acres of Sprawling Campus

Industrial collabrations & Partnerships

Top-Notch Infrastructure

ISO 9001:2015

ISO 14001:2015

AICTE

Diversity at REC

Collaborations & Partnership

Engaged in collaboration with industries, software companies, universities & more.

know moreLatest News

A National Level Hackathon Fest 2024

Raghu Engineering College in association with PSGiTECH and SAP is hosting the regional round of Hackfest 2024 (A National Level Hackathon) on 20th Apr 2024.

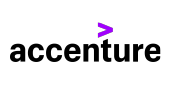

Signal Processing Application

Technical talk on Signal Processing Application in Underwater Communication By Mr.Ch Challam Naidu

𝐅𝐚𝐜𝐮𝐥𝐭𝐲 𝐃𝐞𝐯𝐞𝐥𝐨𝐩𝐦𝐞𝐧𝐭 𝐏𝐫𝐨𝐠𝐫𝐚𝐦 (𝐅𝐃𝐏)

𝐅𝐚𝐜𝐮𝐥𝐭𝐲 𝐃𝐞𝐯𝐞𝐥𝐨𝐩𝐦𝐞𝐧𝐭 𝐏𝐫𝐨𝐠𝐫𝐚𝐦 (𝐅𝐃𝐏) 𝐨𝐧Data Analytics Process Automation By Mr. Pavan Kumar

Machine Learning & AI Workshop .

Mastering the Future : A 2- Day Deep Dive into Machine Learning & AI Workshop .

“Model Smart IoT systems using Arduino and AI”

“Kaidoko supported by IHFC-Technology Innovation Hub of IIT-Delhi Sponsored A Three-day Bootcamp on “Model Smart IoT systems using Arduino and AI”

A THREE DAY’S FACULTY TRAINING PROGRAMME

A THREE DAY’S FACULTY TRAINING PROGRAMME STTP ON EMERGING & CONVERGENT IN ACCESS TECHNOLOGIES

Industrial Visit to BSNL Visakhapatnam

Raghu College Conducted Industrial Visit to BSNL Visakhapatnam

Eye Care Camp

Raghu College Conducted a Eye Care Presented By Dr.V.Krishna Yasaswani

IETE Foundation Day Celebration

The Raghu College Conducted on a Seminar in Evolution of Telecommunications

Chandrayaan Maha Quiz

Get ready to take the Cosmic journey and test your knowledge about the Chandrayaan mission, moon mysteries, and space exploration!

Institutions Innovation Day Celebrations.

Dr. APJ Abdul Kalam's motivational speeches displayed to students on the occasion of Institutions Innovation Day Celebrations.

Skill Development Program

Skill Development Program By Kartik Podugu It's a 2 day's programee

World Space Week Celebrations 2023

The Raghu College celebrating the World Space Week Celebrations on 5th october to 8th october

Programmer’s Day

The Department of CSE celebrated Programmer's Day by conducting Codegolf - Coding contest and Technical Quiz for 2nd year and 3rd year students . It is traditionally observed on September 13 in regular years to correspond to the 256th day of the year.

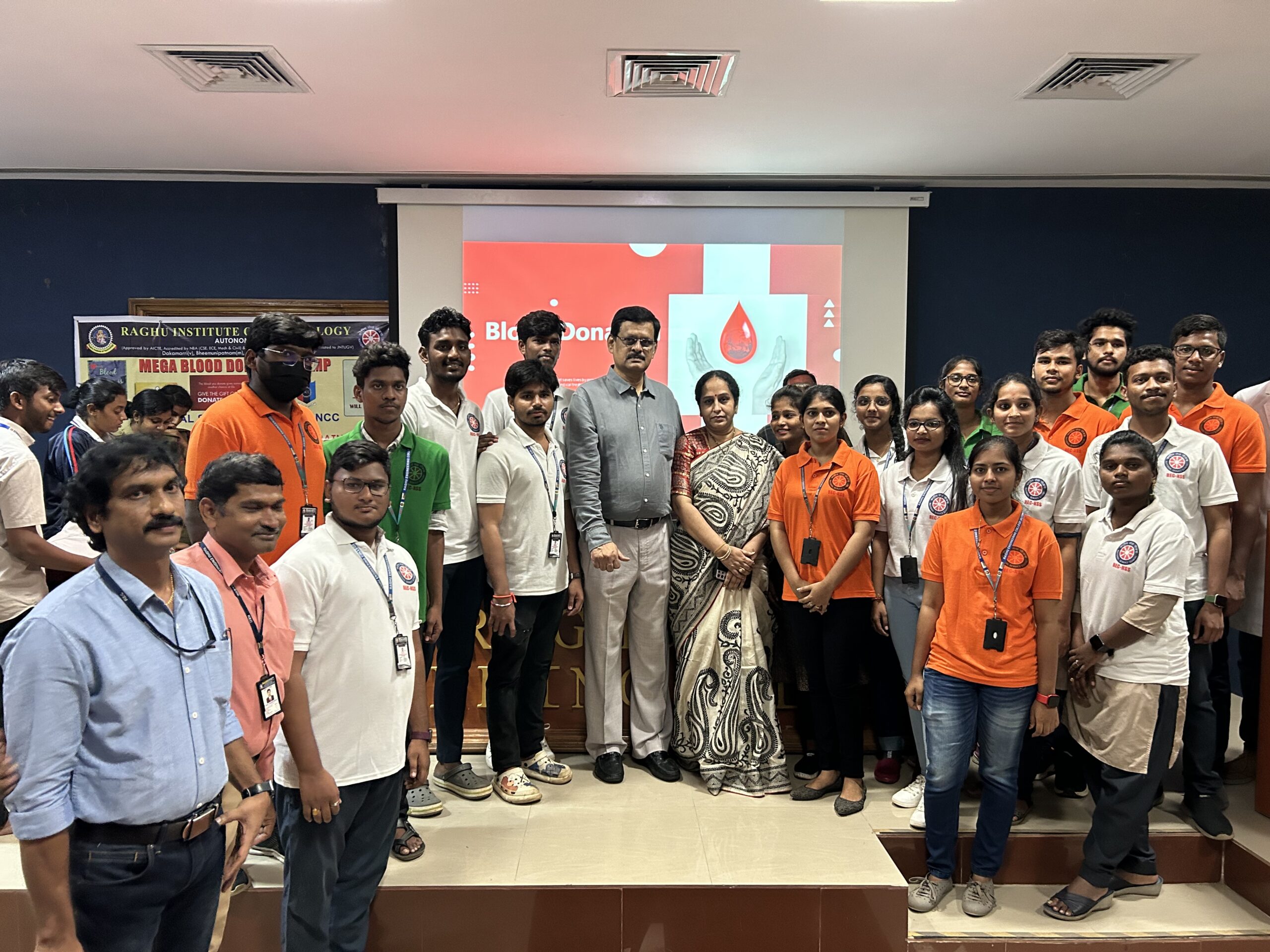

Mega Blood Camp

A Blood Donation Camp was organized by NSS Units , Raghu Engineering Institutions(Autonomous), Visakhapatnam , AndhraPradesh, in association with Indian Red Cross Society, Visakhapatnam..

Innovation/Prototype Validation-Converting Innovation in to a Start-up

IIC Organized a Programme Innovation/Prototype Validation-Converting Innovation in to a Start-up By Mrs.Shaheen

Learn Start-up & Minimum Viable Product / Business

on line Session was Organized By IIC on Learn Start-up & Minimum Viable Product / Business By Proof. M.L.Sai Kumar

Celebrated World Telecommunication Day

Today's event is celebrated to mark the remarkable achievements in the field of telecommunications and to create awareness about the rapid advancements and their impact on society.

Presents Cultural Symposium on 20 & 21st March

Cultural Symposium Events like Dance, singing, Short film , Flash mob, photography, treasure hunt, Conduct by all Raghu's Chakravyuh 2k23 Team

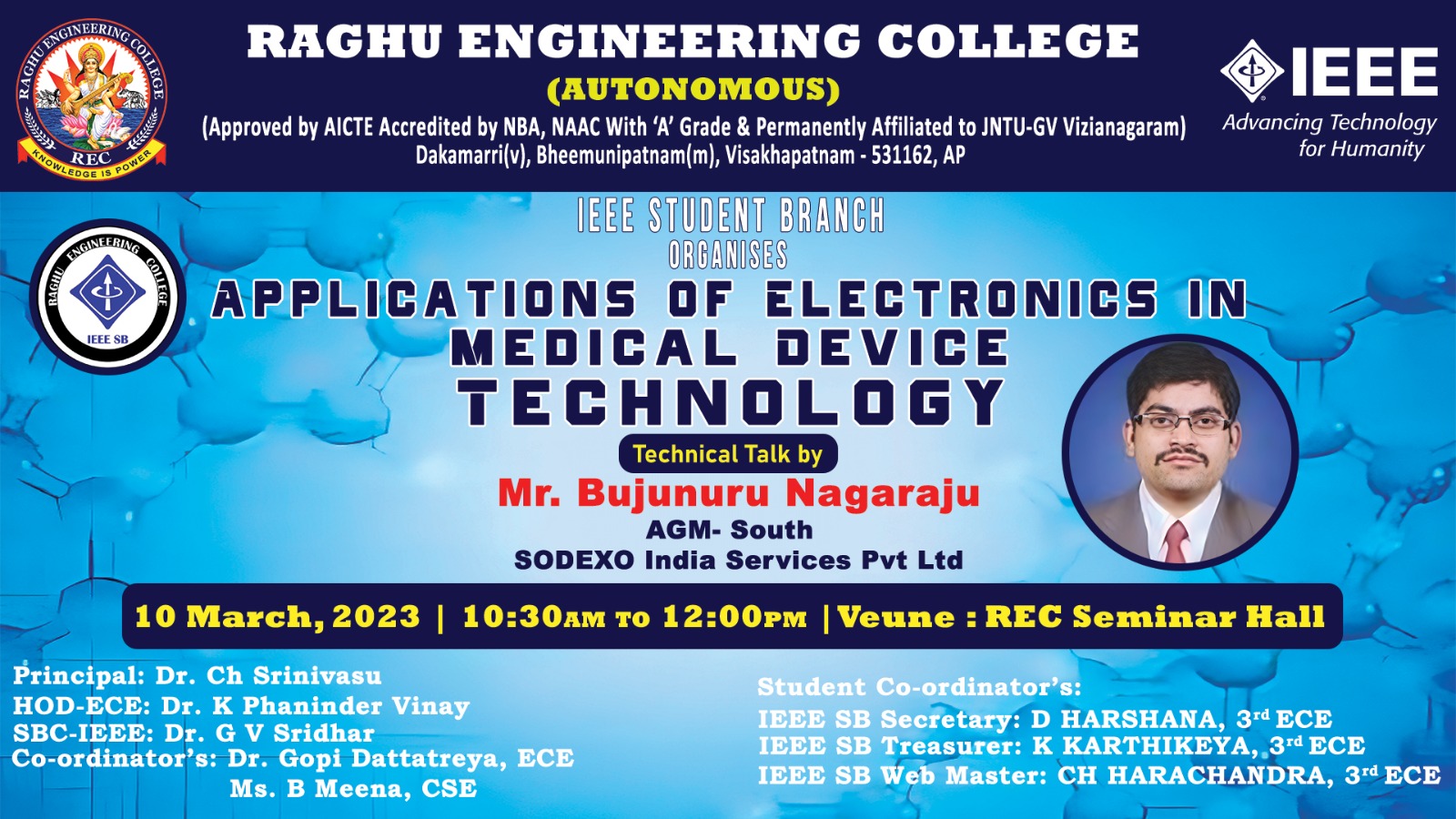

Technical Talk by Mr.Bujunuru Nagaraj (AGM-South SODEXO India Service Pvt Ltd)

IEEE SB, Raghu Engineering College (A), organized a Technical talk on “Applications of Electronics in Medical Device Technology” by Mr.Bujunuru Nagaraju, AGM-South, Sodexo India Services Pvt. Ltd.

CSI Formation Day is celebrated every year on March 6th

The Department of CSE under the CSI professional chapter conducted Guest talk on March 6th 2023 on the occasion of CSI Day Celebration. CSI Formation Day is

CSI Formation Day is celebrated every year on March 6th

The inaugural session was presided by Sri.S.Srinadh Raju , HoD-CSE ,REC , Dr.S.Adinarayana ,HoD-CSE ,RIT and Speaker of the Session Dr.SureshBatha

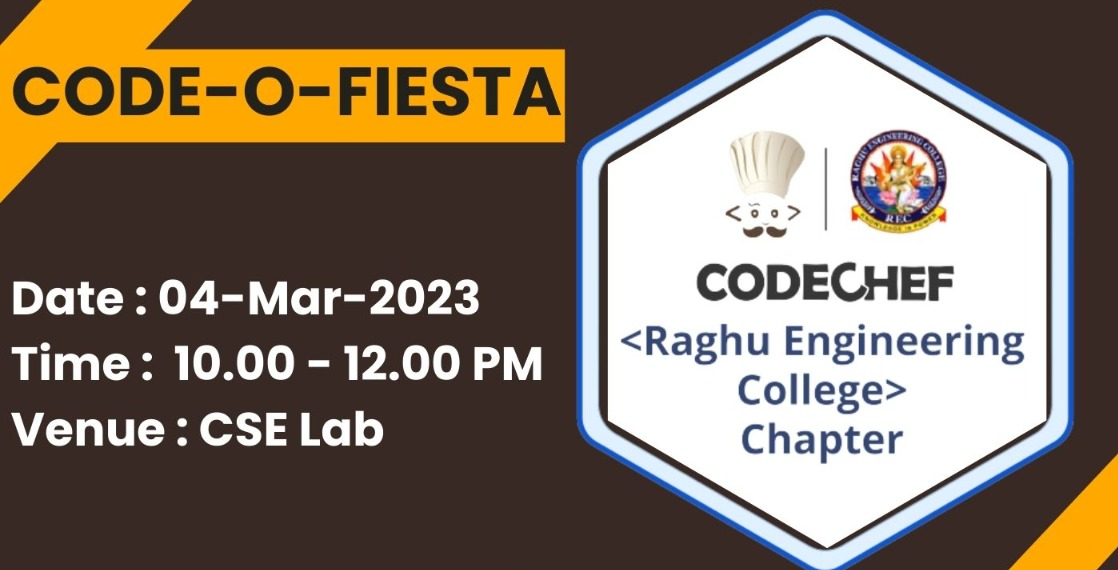

Department of CSE Coding contest under codechef REC chapter on 4th March 2023

Department of CSE Coding contest under codechef REC chapter on 4th March 2023 in this event 120 students participated.

Road Safety Awareness By Sri.S.Raju Sub Inspector of Police

Awareness Program on Road safety to the students was conducted by both NCC and NSS units of the college. The idea is to spread awareness among maximum youth of the country to eliminate the biggest threat of road accidents.

Celebrating National Science Day theme “ Global Science for Global Wellbeing”

IIC Organized a Programme Innovation/Prototype Validation-Converting Innovation in to a Start-up By Mrs.Shaheen

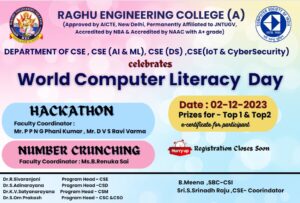

World Computer Day Celebrated By CSE Department

The Department of CSE has celebrated World Computer Day on Feb 15th 2023. On this occasion , The Department has conducted a Quiz competition in CSE Labs .

PROMISING START-UP ECO SYSTEM ENABLER

Raghu Engineering College is awarded with PROMISING START-UP ECO SYSTEM ENABLER at instituitional as well as at individual levels by the Atal Incubation Centre – Sri Krishna Devaraya University (AIC-SKU) during the event “ Start-up Jatara ” held in SKU on 21st and 22nd January 2023.

Our Eight Students got Selected in Kabaddi for JNTUGV University

Congratulations to students(EIGHT IN NUMBER) of Raghu Engineering College who were selected for JNTUGV University Vizianagaram Kabaddi (men) team.

Elected as Executive Commitee Member for Production Engineering of IEI

Dr. P. Jamaleswara Kumar, Professor, Mechanical Engineering is elected as Executive Committee Member for Production Engineering of IEI, Visakhapatnam Local Chapter.